Why is Ventilation so Important for Buildings?

Ventilation is the essential process of replacing stale air with fresh air. Without proper ventilation, buildings become susceptible to stagnant air, where bacteria and carbon make the indoor air more polluted than the air outside.

Why is Ventilation so Important in Air Conditioning?

Ventilation is perhaps the single most important element of any HVAC system. It influences air quality and energy efficiency, and proper ventilation controls odours, dilutes gases (such as carbon dioxide), and inhibits the spread of respiratory diseases. Ventilation air is critical in educational facilities and any type of building or indoor environment where many people congrigate.

Terms Related to Ventilation

Indoor Air Quality (IAQ)

Indoor Air Quality (IAQ) is a term which refers to the air quality within and around buildings and structures. IAQ is known to affect the health, comfort and well-being of building occupants. Poor indoor air quality has been linked to Sick Building Syndrome, reduced productivity and impaired learning in schools.

IAQ can be affected by gases (including carbon monoxide, radon, volatile organic compounds), particulates, microbial contaminants (mold, bacteria), or any mass or energy stressor that can induce adverse health conditions. Source control, filtration and the use of ventilation to dilute contaminants are the primary methods for improving indoor air quality in most buildings.

Determination of IAQ involves the collection of air samples, monitoring human exposure to pollutants, collection of samples on building surfaces, and computer modelling of air flow inside buildings.

IAQ is part of indoor environmental quality (IEQ), which includes IAQ as well as other physical and psychological aspects of life indoors (e.g., lighting, visual quality, acoustics, and thermal comfort).[1]

Natural Ventilation

Natural ventilation is the process of supplying air to and removing air from an indoor space without using mechanical systems. It refers to the flow of external air to an indoor space as a result of pressure differences arising from natural forces. There are two types of natural ventilation occurring in buildings: wind driven ventilation and buoyancy-driven ventilation. Wind driven ventilation arises from the different pressures created by wind around a building or structure, and openings being formed on the perimeter which then permit flow through the building. Buoyancy-driven ventilation occurs as a result of the directional buoyancy force that results from temperature differences between the interior and exterior. Since the internal heat gains which create temperature differences between the interior and exterior are created by natural processes, including the heat from people, and wind effects are variable, naturally ventilated buildings are sometimes called “breathing buildings”.

The static pressure of air is the pressure in a free-flowing air stream and is depicted by isobars in weather maps. Differences in static pressure arise from global and microclimate thermal phenomena and create the air flow we call wind. Dynamic pressure is the pressure exerted when the wind comes into contact with an object such as a hill or a building.

The impact of wind on a building affects the ventilation and infiltration rates through it and the associated heat losses or heat gains. Wind speed increases with height and is lower towards the ground due to frictional drag.

Very broadly, Ventilation in Buildings Can be Classified as ‘Natural’ or ‘Mechanical’.

Mechanical Ventilation of Buildings

Ventilation is necessary in buildings to remove ‘stale’ air and replace it with ‘fresh’ air:

• Helping to moderate internal temperatures.

• Helping to moderate internal humidity.

• Replenishing oxygen.

• Reducing the accumulation of moisture, odours, bacteria, dust, carbon dioxide, smoke and other contaminants that can build up during occupied periods.

• Creating air movement which improves the comfort of occupants.

• Mechanical (or forced) ventilation is driven by fans or other mechanical plant.

• Natural ventilation is driven by pressure differences between one part of a building and another, or pressure differences between the inside and outside. For more information see Natural ventilation.

Natural ventilation is generally preferable to mechanical ventilation as it will typically have lower capital, operational and maintenance costs. However, there are a range of circumstances in which natural ventilation may not be possible:

• The building is too deep to ventilate from the perimeter.

• Local air quality is poor, for example if a building is next to a busy road.

• Local noise levels mean that windows cannot be opened.

• The local urban structure is very dense and shelters the building from the wind.

• Privacy or security requirements prevent windows from being opened.

• Internal partitions block air paths.

• The density of occupation, equipment, lighting and so on creates very high heat loads or high levels of contaminants.

Some of these issues can be avoided or mitigated by careful design, and mixed mode or assisted ventilation might be possible, where natural ventilation is supplemented by mechanical systems.

Typical Mechanical Ventilation Systems for Commercial Buildings

In commercial developments, mechanical ventilation is typically driven by air handling units (AHU) connected to ductwork within the building that supplies air to and extracts air from interior spaces. Typically air handling units (AHU) comprise an insulated box that forms the housing for; filter racks or chambers, a fan (or blower), and sometimes heating elements, cooling elements, sound attenuators and dampers. In some situations, such as in swimming pools, air handling units might include dehumidification.

Where mechanical ventilation includes heating, cooling and humidity control, this can be referred to as Heating Ventilation and Air Conditioning (HVAC).

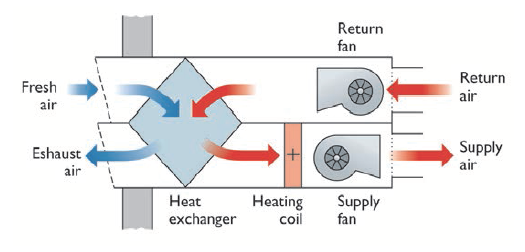

Extracting internal air and replacing it with outside air can increase the need for heating and cooling. This can be reduced by re-circulating a proportion of internal air with the fresh outside air, or by heat recovery ventilation (HRV) that recovers heat from extract air to pre-heat incoming fresh air using counter-flow heat exchangers.

The design of mechanical ventilation systems is generally a specialist task, undertaken by a building services engineer. Whilst there are standards and rules of thumb that can be used to determine air flow rates for straight-forward situations, when mechanical ventilation is combined with heating, cooling, humidity control and the interaction with natural ventilation, thermal mass and solar gain, the situation can quickly become very complicated.

This, along with additional considerations, such as the noise generated by fans, and the impact of ductwork on acoustic separation means it is vital building services are considered at the outset of the building design process, and not seen as an add-on.

Building Management Systems

Mechanical ventilation may be controlled by a building management system (BMS) to maximise occupant comfort and minimise energy consumption. Regular inspection and maintenance is necessary to ensure that systems are operating optimally and that occupants understand how systems are operated.

Building Regulations Requirements

Ventilation in buildings is regulated by Part F of the building regulations. Approved document F includes standards for ventilation and air quality for all buildings and requirements for the prevention of condensation. The types of ventilation covered include; mechanical, passive stack, background and purge (rapid).

It is supported by the Domestic Ventilation Compliance Guide, which provides detailed guidance about the installation, inspection, testing, commissioning and provision of information when installing fixed ventilation systems in new and existing dwellings.

Heat Recovery Ventilation

MECHANICAL ventilation is not something many people would be familiar with in their homes, but it is something many would have experienced in other types of buildings, such as offices and hospitals. Mechanical systems are often regarded as unnecessary for dwellings, but, as our Star ratings encourage us towards better-sealed dwellings, these systems become important. Here I hope to outline the reasons why a truly comfortable and efficient home would include mechanical ventilation with heat recovery (MVHR, also called heat recovery ventilation, or HRV systems).

In MVHR systems, heat is transferred between the air flows in and out to greatly reduce thermal flows while allowing high levels of ventilation.

Air infiltration in homes can account for a significant component of the total heating and air conditioning loads in a building (around a third to a half), and this load can be particularly significant in low-energy buildings where all other loads have been reduced.

At a time when housing sustainability is on many householders’ minds, the best way to increase energy efficiency is to take advantage of the basics of building physics by making improvements to the envelope. This involves using basic passive solar design principles in conjunction with insulation and building sealing.

However, sealing a building does mean you need to consider how the building is then ventilated.

What we refer to as ’natural ventilation’, and what the majority of homes rely on for fresh air, is a combination of open windows and imperfections in construction (gaps and holes). This method of ventilation is largely imperfect¹; good natural ventilation relies on natural variations in pressure and temperature, and the best designs use cross- flow and stack principles to induce air flow into and through a building.

Relying on natural ventilation to provide adequate conditions for good health, as well as comfort, is likely to be insufficient in a well-sealed building. This is because the amount of air infiltration relies on a number of factors, including the time windows are open, openable area and prevailing weather conditions. Mechanical ventilation provides a way to address this, using fans to move air into and/or around a building. A number of studies have also shown that the use of MVHR can be more efficient, in terms of reduced energy use and the resultant carbon emissions, than relying on natural ventilation. As with any system, appropriate system selection and design is key.

Why is Adequate Ventilation so Important?

Adequate ventilation within a building ensures good air quality, by removing toxins and CO2, and also helps to control humidity, thus reducing the risk of condensation. Energy efficiency and thermal comfort can also be enhanced. Air quality can be affected by a number of impurities, such as low-level irritants (dust, pollen) right through to radon and volatile organic compounds. In humid or colder areas, and particularly in uninsulated buildings, there is also a significant potential for condensation when humidity levels are too high, and this can result in mould growth and various health issues. Building fabric can also be affected by moisture and deteriorate, reducing the life of a building and adding to life-cycle costs.

Why Use Mechanical Ventilation?

A mechanical ventilation system can:

•remove stale air and introduce fresh air into a building assist with reducing indoor humidity levels

•reduce incoming pollutants, when effective filtration is included

•remove indoor pollutants, including CO2 and VOCs from off-gassing of materials such as those used in furniture and finishes.

Studies show that to ensure adequate ventilation by natural means, the windows in a reasonably well-sealed building would have to be opened at least four to six times a day for a reasonable amount of time.

Who Does it Work For?

One of the most important things to get right before introducing a MVHR system is your building sealing—for what is the point in controlling the ventilation and attempting heat recovery when your building leaks like a sieve anyway? It’s similar to turning on the heater while you have all the windows open— fighting the classic ‘losing battle’.

In order to be successful, ultra-low energy buildings require a very good level of airtightness. Once a building is airtight, it then becomes necessary to introduce ventilation in order to make the building habitable.

Types of Systems

The simplest mechanical ventilation system uses exhaust fans only, with fixed inlets to provide makeup air. There is no heat exchange on this system, so incoming air is the same temperature as ambient. Exhaust points would likely be provided in areas such as bathrooms and kitchens.

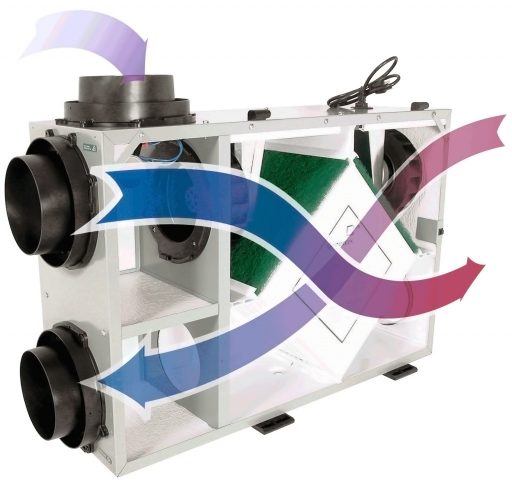

Another simple system is a two-way ventilator, which operates on a push-pull basis to generate a flow of supply and exhaust. These ventilation systems operate with one fan unit exhausting and the other supplying air.

An integrated heat recovery heat exchange bank is used to transfer heat between exhaust and supply air streams.

At the other end of the scale, a fully-ducted ventilation system is the most effective solution, and utilises fully controlled and balanced ventilation. This type of system is most effective when applied in a well-sealed building, where other infiltration sources are reduced (note: this does not preclude openable windows!) These systems supply fresh, filtered air to the building, where it then flows through the building before being exhausted back to outside, thereby removing hot or humid air. The air volume supplied is balanced with the exhaust.

The most efficient way to operate such a system is to include heat exchange, whereby thermal energy is transferred between the outgoing and incoming air streams, keeping the internal conditions stable and retaining that energy. Bypass arrangements are possible on these heat exchangers, to take advantage of times when outdoor conditions are good enough for direct air supply.

Heating and/or cooling coils can be added to the more complex MVHR systems, and radiant or refrigerant systems (split systems or radiant panels) can be located internally to provide any additional heating or cooling requirements.

What to Look For

Like everything, it’s about selecting the system that’s right for the application. There is reduced benefit from installing a heat recovery system if the issue of building sealing first hasn’t been addressed, as uncontrolled air infiltration will negate the effectiveness of your mechanical system.

Units should be selected based on predicted ventilation requirements (a function of occupancy and heat loads) and then size.

The unit should be selected for high thermal exchanger efficiency. A good unit will have a sensible (related to temperature) heat exchange efficiency of greater than 80% (it can be up to 93%). However, a reasonable efficiency could be around 75% and such units will typically be more affordable.

Electrical efficiency should also be considered (energy consumption per m3 air delivery—less than 0.45 Wh/m³ is excellent).

Controls can be as complex or simple as desired.

For advice on ventilation please call us on Coventry Tel: 024 7624 9440 or email us at sales@chillaire.co.uk / 16 Lythalls Lane, Holbrook, Coventry, CV6 6FG